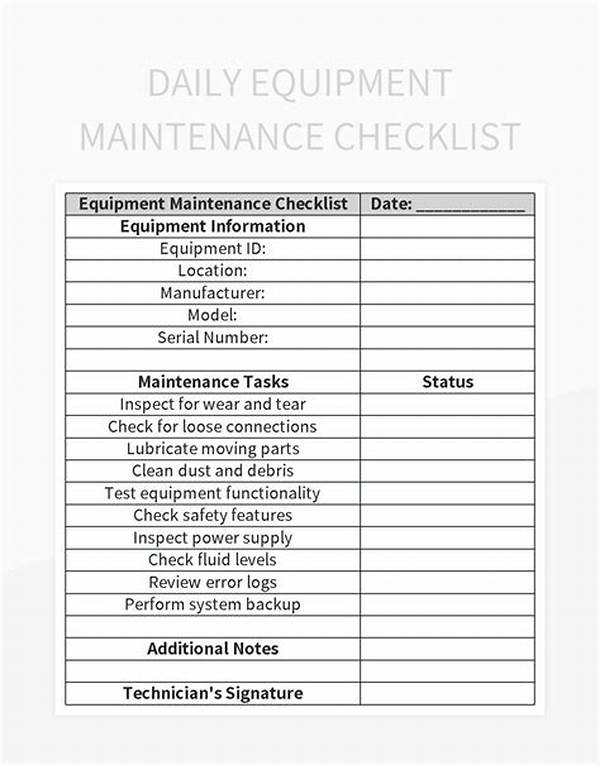

Instrument Maintenance Checklist for Technicians

In the dynamic world of technology and machinery, the role of a technician is indispensable. Imagine a maestro conducting an orchestra with precision and harmony. This is akin to how a skillful technician operates, ensuring that every instrument works flawlessly, performing at its peak. But how does one ensure the seamless functionality of these complex systems? Enter the instrument maintenance checklist for technicians—a vital tool that acts as a roadmap for systematic and consistent maintenance.

Read More : Ent Instruments Used In Hospitals And Ent Clinics

The checklist serves as a comprehensive guide, akin to a treasure map that leads technicians to the ultimate goal of optimized equipment performance. With precision and attention to detail, technicians can avoid the chaos and consequences of malfunctioning instruments. The checklist is not just a list; it’s a compilation of insights, experiences, and proven practices that embody the wisdom of seasoned technicians.

Technicians are the unsung heroes who ensure everything ticks like clockwork. From the buzzing electronics in our gadgets to the towering machines in industrial settings, technicians have their work cut out for them. A robust instrument maintenance checklist for technicians brings a sense of order in this intricate world, offering a structured path to follow with a preventative approach. This article delves into the fascinating world of maintenance checklists—joined with humor, market analysis, and storytelling flair.

The Importance and Benefits of a Checklist

Imagine facing a cluttered workstation with a tangled mess of wires, gadgets, and tools—a technician’s nightmare. Without a checklist, things can quickly spiral into a chaotic mess. The instrument maintenance checklist for technicians acts as a trusty sidekick, ensuring efficiency and methodical operation. It prompts the technician to examine each piece before giving it a clean bill of health. When you have a checklist, addressing overlooked issues becomes significantly easier, cutting down unexpected downtimes, spiraling costs, and potential hazards.

Purpose of an Instrument Maintenance Checklist for Technicians

A meticulously crafted instrument maintenance checklist for technicians has become the backbone of maintaining functional integrity and operational excellence. The purpose of this checklist transcends the mere ticking of boxes; it provides a deeper understanding and scrutiny of each component within an ensemble of instruments. Technicians can harness this tool to optimize performance and prolong lifespans, ensuring machines operate at their zenith.

Clarifying Roles and Responsibilities

With an instrument maintenance checklist, technicians can slice through ambiguity. This guide clearly defines roles, aiding technicians to focus on their core responsibilities without duplicating efforts. A technician can easily glide through his tasks without missing a beat. Think of it as a well-rehearsed play where each technician knows his lines. It becomes simpler to hold each team member accountable and ensures high standards are maintained.

By aligning expectations and responsibilities, a checklist orchestrates a synchronized team effort. This unified approach helps technicians diligently examine every bolt and joint, ensuring no stone is left unturned. A comprehensive checklist forms the foundation of a culture committed to excellence.

Quality Assurance and Performance Optimization

When technicians have a detailed instrument maintenance checklist, they step into a realm where quality isn’t just a buzzword but a guaranteed outcome. By following the list, they ensure all procedures adhere to the highest standards. Whether it’s calibrating a delicate sensor or inspecting robust mechanical systems, the checklist is a mantra that fosters consistency and quality assurance in every task.

A comprehensive checklist moves beyond mundane routine checks—it’s a tool that aids in systematic analysis and innovation. Technicians can identify opportunities for enhancements, paving the way for advancements and optimizations. Embracing the checklist means embracing a pathway to relentless improvement, an ethos that champions precision.

Maximize Productivity with a Structured Approach

The structured approach fostered by a maintenance checklist propels productivity levels to new heights. With a clearly outlined schedule, technicians can slot their time effectively, maximizing productivity. This organization is critical for deadline-driven environments, ensuring tasks are carried efficient manner without compromising quality.

Equip your team with this powerful tool. Not only do you simplify daily operations, but you instill a culture that values rigorous standards and proactive strategies. The forward-thinking corporation understands that the benefits reaped from such a systematic approach far outweigh the time invested in checklist preparation.

Practical Applications of an Instrument Maintenance Checklist

Boosting Efficiency and Reducing Cost

The adept use of an instrument maintenance checklist empowers technicians to identify potential issues before they escalate, effectively reducing costs associated with unexpected repairs and downtime. This preventive approach ensures machines are continually operating at optimal levels—a boon for any business seeking to refine operations and financial stability.

Read More : Tips For Choosing A Carbon Fiber Bow For A Modern Cello

Checklist for Effective Maintenance

The seamless integration of checklists into everyday maintenance routines is pivotal. Allow your team to extract tangible value from their efforts by implementing these practical steps. When the instrument maintenance checklist for technicians becomes a habitual practice, it transforms the operational dynamic into one driven by efficiency and cost-effectiveness.

Creating the Ultimate Checklist for Technicians

Step-by-Step Guide to Crafting a Checklist

To design an effective instrument maintenance checklist for technicians, begin with brainstorming the critical components and tasks specific to your operations. Engage with technicians and stakeholders in a collaborative approach, ensuring that every aspect of the checklist is thorough and applicable.

Once a draft has been created, test it in a real-world setting. This iterative approach encourages refinement and ensures the checklist is polished and actionable. Don’t hesitate to incorporate team feedback and continuously evolve the checklist to stay relevant with new technologies and systems.

The checklist becomes not only a routine guide but a document of expertise. Its completion marks a job well done, creating a symphony of mechanical harmony orchestrated by adept technicians.

Thoughtful Implementation and Continuous Evaluation

An instrument maintenance checklist thrives when implemented with thoughtfulness and evaluated continuously. Senior technicians should pave the way, demonstrating the value and efficiency driven by checklists in action. Remember, these checklists should remain dynamic, reflecting changes in technology and procedural updates.

By evaluating the checklist’s effectiveness regularly, you open the door to constant improvement, fostering an environment dedicated to innovation. Embrace it fully, and witness how it reshapes the way your technician crew transforms challenges into achievements.

Final Thoughts on Embracing Maintenance Checklists

As technicians adopt an instrument maintenance checklist, they become proactive sentinels of the maintenance world. With these intricately laid out checklists, they ensure safety and peak performance. The utility of these checklists extends beyond mere maintenance—it revolutionizes operational efficiency. Share your expertise, synchronize your efforts, and watch as a culture of excellence unfolds.

By extending these benefits across your organization, you create a network of informed decision-makers and empowered technicians, celebrating the zenith of operational and technical excellence.